Below you will find the lecture that Diederik Jaspers gave at the KiVi lustrum about the energy transition.

Good morning fellow KiVi members, thank you for attending this lecture on circularity.

To warn you in advance: this lecture contains good news regarding the climate…

I want to tell you about our vision of how we see the Energy Transition developing in the future. After thirty years of working in the development of sustainable technologies, I ran into old classmate Wouter van Neerbos, who had worked at Shell for 25 years. Opposites attract! After a lively discussion, we soon came to a joint vision, which we are now actually implementing with the company OBBOTEC and Circonica.

Partners Accelerated Carbon Transition ofwel PACT is een initiatief met een gezamenlijke visie op de Energietransitie. Deze visie is gebaseerd op de laatste technologieën, integratie, circulariteit, en samenwerking tussen bedrijven en sectoren.

We believe that the technologies to realize the energy transition are already developed and available. If we start now, together we can already lay the foundations in 2030 to achieve the Paris goals for 2050. Our goal is to propagate this vision widely and to connect as many partners and technologies as possible to build a coalition and thus significantly accelerate the energy transition.

What does this vision look like?

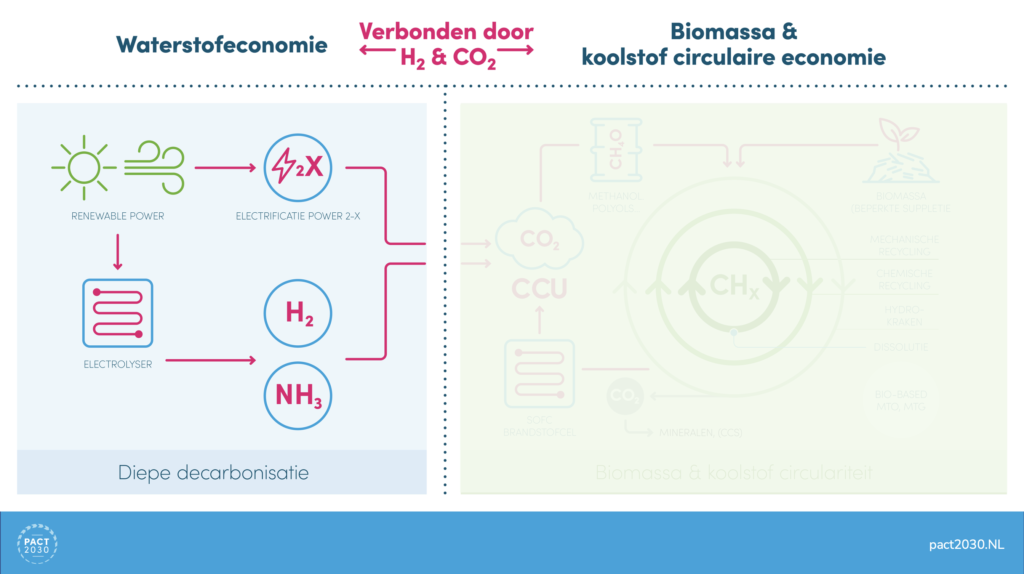

On the one hand, there is the vision to decarbonize, or the hydrogen economy.

Hydrogen can be produced from sustainably generated electricity by means of water electrolysis. This hydrogen can be used directly as a raw material or fuel, or converted into ammonia, for example. Another route is to directly synthesize chemical substances with it. The most well-known is chlorine, but there are many other possible substances. TNO is investigating this in the Voltachem project.

However, ….., this is not complete. It is difficult to make plastics with only hydrogen. And fuels with carbon have an excellent energy density.

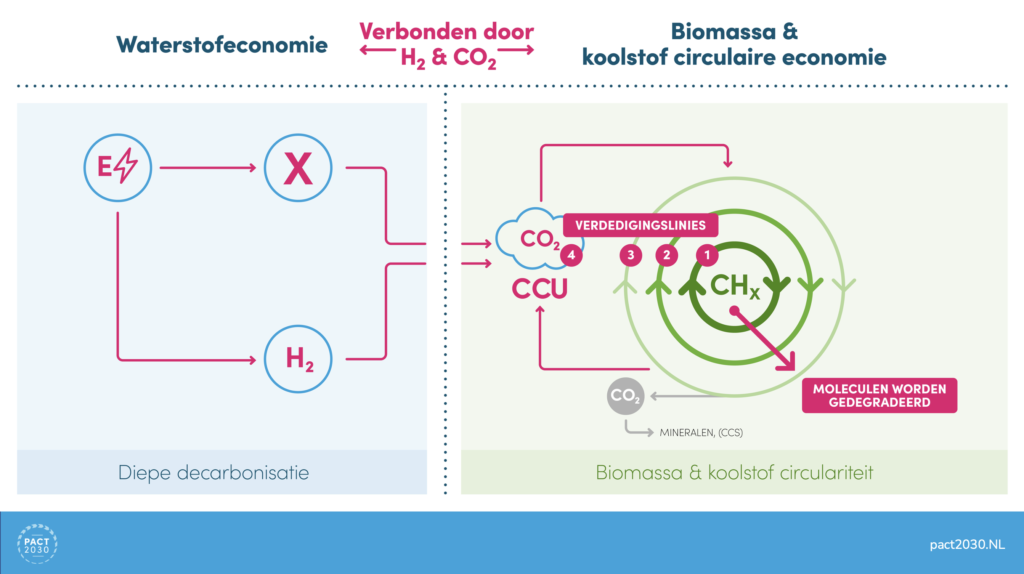

PACT 2030 believes that the energy transition can still be based on the use of hydrocarbons and can be achieved without a total carbon phase-out;

The problem is not the carbon itself, but the fact that it leaks as CO2 to the atmosphere.

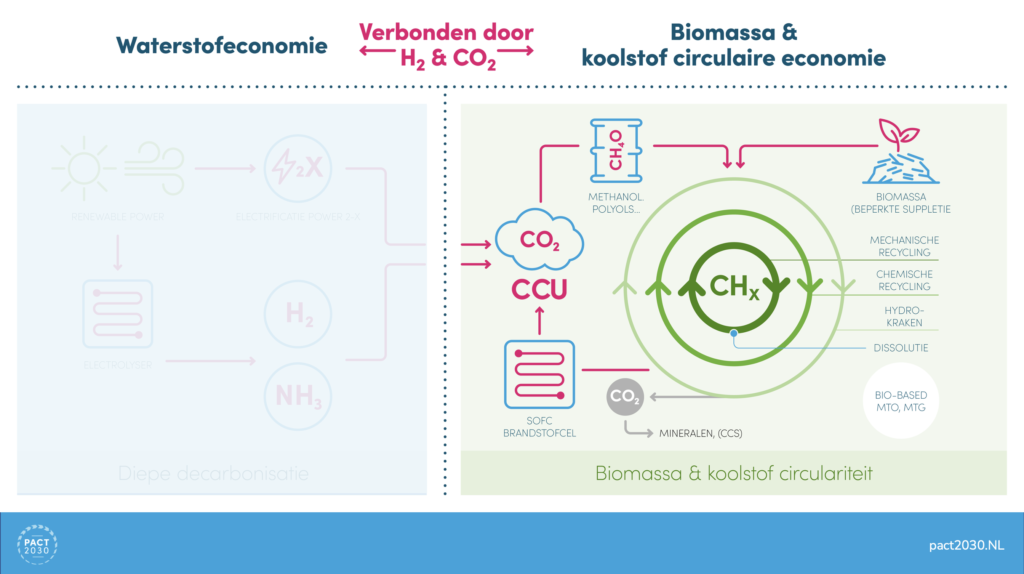

Therefore, carbonaceous streams should be centered around the circularity of carbon , or closing the carbon cycle. This can be done by recycling and reusing carbon-containing polymers, fuels and CO2 instead of phasing out carbon. Processes must be used that keep the substances in the inner rings as high-quality as possible. This is analogous to Lansink's Ladder. And that as little dust as possible leaks to a lower level outside the rings, a kind of defense lines. It is best to stay in the inner ring with the shortest recycling loop: this includes reuse and mechanical recycling. Dissolution of plastic waste back to near-virgin plastic is also a very short loop, more on that later.

Chemical recycling to monomer from Ioniqa is in the next ring and beyond that are fuels, such as hydrocracking from residual biomass waste.

Leakage of carbon from these rings can never be completely prevented, so to close these chains the released CO2 is reused. Permanent CO2 storage or CCS is currently in the picture. But conversion via intermediates back to high-quality substances makes the carbon circular.

Processes for conversion via methanol to fuel or olefins for plastics (MTG and MTO) and polyols for PUR have already been developed. And the synthesis of e-fuels/e-kerosene with gas-to-liquids.

In this way, carbon from CO2 becomes circular. The remaining carbon leakage can be supplemented with a limited flow of biomass from residual flows.

But of course all this almost never goes without a supply of energy.

This is where integration with the hydrogen economy comes into play. A lot of hydrogen is needed for chemicals and fuels. This means a lot of ambition for the generation of sustainable electricity, after all, much more is needed than just power supply. And the industry also has to work on efficient water electrolysis on a GW scale. Shell recently started this with the announcement of a 200 MW water electrolysis pilot.

To make this vision completely concrete, there are a number of key technologies that make this system a reality. On the left side these are high temperature solid state electrolysers SOEC due to their very high efficiency. These are still early in development so the tried and tested alkaline variant will pick this up first. To the right of carbon circularity, these are processes that have a high yield, such as plastic-to-plastic with dissolution and hydrocracking of residual biomass waste from OBBOTEC. Solid fuel cells, SOFCs, from e.g. Circonics convert fuels into concentrated CO2, which are well suited for reuse to methanol and new fuel.

Finally my last sheet with a picture of SPEX, the dissolution process of OBBOTEC.

This is the opening of the SPEX pilot with 4x 3 m3 pressure reactors at Plant One Rotterdam by then alderman Bonte. Here, practical waste streams from well-known companies such as Unilever are tested at almost full scale. In the first step, only the olefins PE and PP are selectively dissolved, other polymers and impurities remain behind. After filtration cycles and washing steps, precipitation follows under controlled conditions. The product is then stripped of the solvent and can be sold for compounding. The solvent is almost completely recycled after condensation.

This is the end of my presentation on transparency. Thank you for your attention and we are now ready for any questions.

Diederik Jaspers graduated in Delft as a chemical engineer with a specialization in Inorganic Chemistry focused on energy and the environment. In addition, he gained knowledge of business economics by obtaining an MBA at the Erasmus University Rotterdam. Diederik has over 20 years of experience in energy conservation, sustainable energy, innovation, ceramic membranes and fuel cells. The focus is on the large companies in the industry.